When most people think of 3-D printing, they think of children’s toys, architectural models and other general services. The idea of 3-D printing being suitable for other things, such as making drugs, is something that will take many people by surprise, but contemporary eCommerce business solutions, like online design tools, make realistic.

The technology used for 3-D printing has been around since the 1980s, but it is only recently that it has become affordable for the mainstream, and that it has become sophisticated enough to explore more unusual uses. The biological applications of the technology – for things like custom prosthetics and drug making – are something that we are just starting to appreciate.

The applications of 3-D printing became truly apparent relatively recently when Aprecia Pharmaceuticals announced that the FDA had approved SPRITAM as a drug for the treatment of epilepsy. SPRITAM is the first drug to be manufactured using 3-D printing technologies.

Don Wetherhold, the CEO of Aprecia, said that SPRITAM is designed to offer patients who are struggling with other drugs an alternative choice, and to transform the way that patients experience medication. There are plans to make SPRITAM available on the markets early in 2016.

The drug is designed to be used as a high dosage treatment, and uses something called ZipDose technology, which means that the drug is a new form of tablet. The layers of the powdered drug are 3-D printed and bound together, and any excess powder is then blown away. This means that the drug will dissolve far more quickly than the average pill. This means that it will be easier for people who require high doses of medication to get the dose they require, freeing them from large and hard to swallow pills.

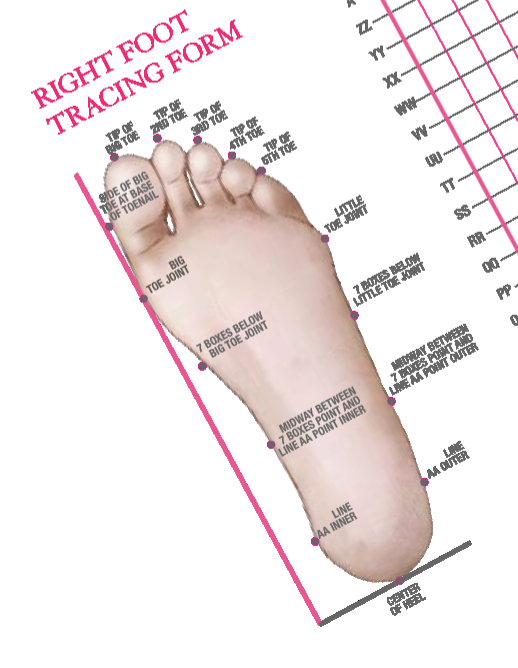

3-D printing is an amazing technology, and we can expect to see many more innovations based on it over the last few years. From fashion to technology and medicine, today it is easier than ever to make exactly what you need, the way you need it, improving your quality of life. Such businesses as Drugs online design and shoes online design are exist due to in fact the same software for online design.